The first working 3D printer – or as the process was termed back then, stereo lithography – was created way back in 1984 by Chuck Hull of 3D Systems Corp. Since the beginning of the 21st century, there has been a large growth in the sales of these machines, and is set to grow further now that their price has dropped substantially. According to Wohlers Associates, a consultancy, the market for 3D printers and services was worth US$ 2.2 billion worldwide in 2012, up 29% from 2011. As producers become more familiar with the technology, they are moving from prototypes to finished products. Last year, Wohlers reckons more than 25% of the 3D-printing market involved making production-ready items. [1]

3D printers make things from a particular material by building them up one layer at a time, rather than the traditional method of removing material by cutting, drilling or machining – which is why the process is also called ‘additive manufacturing.’ Based on the requirements, there are many techniques used in 3D printing, and with changes needed to be made on just the software level, multiple items can be manufactured without the need for costly retooling of machines. This has made 3D printing a popular way to make one-off items, especially prototype parts and craft items.

One of the most popular techniques is Fused Deposition Modeling (FDM), where an electrically heated nozzle forces out a wire or filament of thermoplastic, which sets as it cools. Multiple heads can extrude different colours. FDM is the mechanism used in many of the small 3D printers used by hobbyists, and they have become more affordable. More capable 3D printers cost much more and big industrial systems, like laser-sintering technique using machines which are capable of printing aerospace parts in titanium, cost as much as one million dollars.

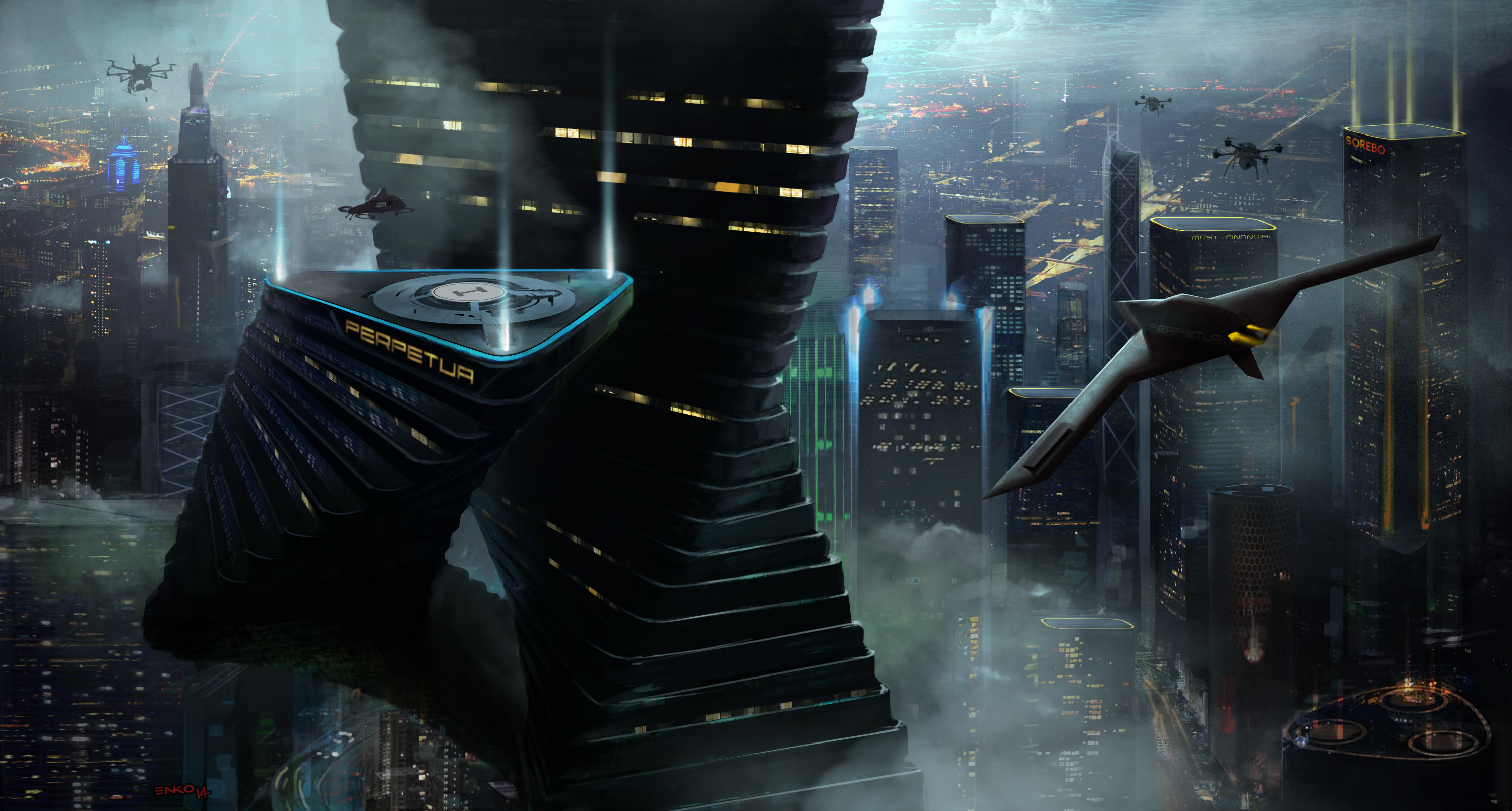

Bringing 3D printing into the home

The main obstacle keeping the process from going mainstream is that in order to print something, you first need a digital model from a CAD programme turned into a series of cross section data to tell the printer what to make. Models for many common objects are freely available online. However, if you wanted to print a model of a rare or custom piece, you would have to create a digital model on your own.

That’s where the MakerBot Digitizer comes in – a desktop device that scans any object up to about 8 inches in diameter. Just place an item on its rotating platform, and the Digitizer uses two lasers and a webcam to create a 3D digital file of it within minutes. Once the digital scan is completed, an object can be manufactured right away by feeding the resulting file to a 3-D printer, which is much easier and faster than using software to design a digital model from scratch.

For example, if you lose a piece from your favourite chess set, you can simply scan one of the remaining pieces and print a replica that will be identical in size and shape though maybe not in colour or weight. More significantly, astronauts aboard the International Space Station could scan and print replacement parts for broken or lost components instead of having to wait weeks for them to be delivered. [2]

Competing with Mass Manufacturing

While 3D printing has been getting a lot more attention recently, most people still see it as more of a fad or novelty. Despite the great strides in 3D manufacturing, it is not about to be used for mass manufacturing any time soon. Even though the technology is improving, the finish and durability of some printed items can still be short of the standards required. Additive manufacturing is also much slower and 3D printers can’t churn out thousands of identical parts at low costs.

3D printers do, however, have their advantage, which is why they are being used by some of the world’s biggest manufacturers such as Airbus, Boeing, GE, Ford and Siemens. Production of spare parts for older components which are out of production, development of prototypes, customised hearing aids, plastic dental braces or even prosthetic jaw bones are just some of the current commercial uses for 3D printed components.

In the US, the new F-35 fighter jets manufactured by Lockheed Martin have up to 900 parts identified that could be produced using 3D printing. The Chinese aeronautics industry also started using 3D printed titanium components and has some of the largest additive printing machines in the world, recently producing a whopping 5-meter long titanium part. [3]

Future of 3D Printing

The significance of 3D printing in mass production will rise with the development of systems that are capable of printing electrical circuits directly onto or into components. The process uses specially treated silver which can be printed using an inkjet. Using this process will also reduce waste that occurs during chemical etching for conventional circuitry. A trial system for printing mobile-phone circuits directly into the handset case was recently installed on a production line in China. If successful, it could result in slimmer phones or more room for additional electronics, or even larger batteries within a mobile phone shell.

Calling 3D printing a novelty is definitely not justified, and while the average domestic user may not really have a need for it on a regular basis just yet, you can still use the nearest 3D printer to perhaps make a replacement for a minor vehicle part, broken cupboard handle, a protective case for a phone or any other valuables (and hopefully not to print a gun). [4]

3D printing could have a significant impact in markets such as Sri Lanka where access to customised manufacturing is limited. Much further in the future, there are plans to use a combination of bio materials and 3D printing for producing food – even tissues and organs. You are going to hear a lot more about and quite possibly use a 3D printed product in the near future.

- http://www.economist.com/news/technology-quarterly/21584447-digital-manufacturing-there-lot-hype-around-3d-printing-it-fast

- http://edition.cnn.com/interactive/2013/11/tech/cnn10-inventions/?hpt=te_t1

- http://www.thomasnet.com/journals/machining/additive-manufacturing-taking-flight-in-aerospace/

- http://www.forbes.com/sites/andygreenberg/2013/11/14/3d-printed-gun-stands-up-to-federal-agents-testfiring-except-when-it-explodes-video/

Image Credits : livescience.com, wired.com, foxnews.com, makerbot.com

Yesterday, I realized there’s a 3D printing service in Sri Lanka – see http://www.yamu.lk/place/3d-concept-studio.html

nike air max 90

Well, I just realized how easy it is now to get 3D printing in Sri Lanka with Sigma X. http://sigmaxdesigns.com/ I got a very good deal thanks Sigma X.